tear strength fabric testing|tearing strength tester : OEM There are two separate tear strength testing methods: tongue tear and trapezoidal tear. They both require specific preparations in order to be accurate. As the names suggest, in tongue tear tests the fabric is cut to form . Synopsis. Seth Davenport is masquerading as a small town Iowa preacher in the hopes of starting a full-blown insurrection against the status quo, unaware that an industrialist tycoon has hired a professional .

{plog:ftitle_list}

web17 de mai. de 2023 · D'après l'ouvrage Atlas Of An Occupied City, Amsterdam 1940-1945 de Bianca Stigter. Le film propose un portrait croisé : à la fois une immersion dans la .

The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in . Tear strength is a material property that determines the amount of force required to propagate a tear in a fabric. It is typically measured in pounds-force (lbf) or Newtons (N) and serves as a measure of a fabric’s resistance to .What Is Fabric & Textile Tear Strength? Tear strength is the measurement of the resistance of fabric against tearing. It actually relates to the individual yarns in the fabric. There are three basic fabric and textile tear test ing methods. .

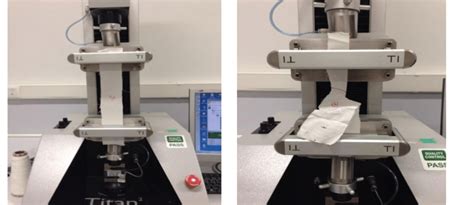

There are two separate tear strength testing methods: tongue tear and trapezoidal tear. They both require specific preparations in order to be accurate. As the names suggest, in tongue tear tests the fabric is cut to form . Q: What are the relevant standards of textile tearing strength testing? At present, the most commonly used method of fabric tearing strength test is mainly the pendulum method, tongue method and trapezoidal method. Aside from these three methods, there is also Wing method, rectangle method and nail method used nationally. Table 1 shows the relevant. 2.Tear strength test. a.Pendulum method. Apparatus and Material; Pendulum fabric tear strength tester (Figure 1), steel ruler, scissors, a few pieces of fabric, etc. figure 1: Elmendorf Tearing Tester . Test principle; The sample is fixed in fixture, with a cut on it. The pendulum in the position of max potential energy is released.

A tear starts with a snag on clothing etc., then the fabric has a small cut in it, so if the force continues the fabric will then tear. The cut before testing is to help with tear propagation. Q: What type of load cell to use and calibration certificate to request if we have test fabrics with tear strength between 10 and 100 newtons? Imagine the unwavering strength of Hercules applied to your favorite fabric. When you consider tensile strength, you're fundamentally looking at a material's ability to resist breaking under tension. High tensile strength is essential for ensuring that fabrics don't tear easily, especially when used in demanding applications like outdoor gear or heavy-duty .

ASTM D1424 is a widespread test approach evolved by the American Society for Testing and Materials (ASTM) for determining the tearing strength of fabric using the Elmendorf tear test equipment. This method is widely recognized and utilized in various industries, inclusive of textiles, clothing, and packaging. Here is the significance of tear strength according to the use of fabric in different industrial sectors. Apparel; Tear strength ensures the garment’s better lifespan and comfort. Industrial Textiles Fabric tear strength test is a very important parameter for industrial textiles that are used in construction and safety equipment. Medical TextilesOriginally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method applies to most textile fabrics, including those that are treated and untreated, woven, knitted, or unwoven.

textile tearing strength test

Types of materials for tear testing: A tear test is generally only performed upon flexible materials as they are more susceptible to accidental fractures and punctures as well as partial ruptures (tears and holes). The more common materials that benefit from tear testing are textiles, fabrics, elastomers, rubbers, polymers, packaging and paper . 5.2 The force registered in a tear test is irregular, and as a consequence, empirical methods have had to be developed to obtain usable values related to tear strength. In spite of the empirical nature of the reported values, the values are considered to reflect comparative performance of similar fabrics tested and measured in the same way. Understanding tear testing: Tear strength refers to a fabric's resistance to tearing or propagating a rip when subjected to external forces. It specifically measures the force required to initiate and continue a tear in the fabric, often in a specific direction. Tear strength is influenced by factors such as fabric construction, yarn properties .This test allows manufacturers to determine the strength of the sample. This test complies with the following standards: ASTM D1004 Standard Test Method for Initial Tear Resistance of Plastic Film and Sheeting, and ASTM D5587 Standard Test Method for Tearing Strength of Fabrics by Trapezoid procedure.

A tear strength test is often required for woven fabrics used for applications including army clothing, tenting, sails, umbrellas and hammocks. It may also be used for coated fabrics to evaluate brittleness and serviceability. The Elmendorf Tear Strength Tester is an instrument specially used to test the tear strength (strength) of fabrics. It uses the impact pendulum method to measure tear strength, also known as the pendulum or falling .

The tongue tear method is often used to measure the tear force and the tear strength of a fabric specimen. This method, outlined by ASTM D2261, requires a specific sample preparation where the rectangular fabric .

For example, with rubber, tear resistance measures how the test specimen resists the growth of any cuts when under tension, it is usually expressed in kN/m. [2] Tear resistance can be gauged via the same ASTM D 412 apparatus used to measure tensile strength, modulus and elongation.ASTM D 624 can be applied to measure the resistance to the formation of a tear . 1.2 This test method applies to most fabrics including woven, layered blankets, napped pile, blanket, and air bag fabrics, provided the fabric does not tear in the direction crosswise to the direction of the force application during the test. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing .This test method measures the sewn seam strength in woven fabrics by applying a force perpendicular to the sewn seams. . Tear properties of fabrics. Determination of tear force of tongue-shaped test specimens (double tear test). Experience our recommended textile testing equipment adherent to BS EN ISO 13937-4 here. BS EN ISO 14125:1998 :

Tear test specimens are pulled on a tensile tester at a cross-head rate of 8.5 millimeters per second (20 inches per minute). . Fabric tear strength is generally susceptible to changes during processing 92 (dyeing and finishing), due to the changes in fibre and yarn friction and mobility, particularly the latter. Nevertheless, any fibre .1.3 Tearing strength, as measured in this test method, requires that the tear be initiated before testing. The reported value obtained is not directly related to the force required to initiate or start a tear. 1.4 Two calculations for trapezoid tearing strength are provided: the single-peak force and the average of five highest peak forces.

What is Elmendorf Tear Tester?. The Elmendorf Tear Tester is a widely used instrument in material testing. It is specifically designed to measure the tear resistance of various materials, including films, paper, textiles, and non-woven fabrics.This testing method helps in assessing the material’s ability to withstand tearing forces, providing valuable insights into its quality and .Textile Testing IFAI Expo 2017 New Orleans, LA Jan P. Ballard . Characteristic Minimum Requirements Test Method Breaking Strength (load) 150 lbf, min ASTM D5034 . 15 lbf ASTM D434* Tear Strength 10 lbf ASTM D1424 Dimensional Change 3% max AATCC 135 Colorfastness-Burnt Gas Fumes-2 cycles Class 4 (a) AATCC 23

tearing strength tester

Factors affecting tear strength; Measurement of fabric tearing strength; Bursting Strength. Fabric Bursting Strength; Measurement of Fabric Bursting Strength; Pilling and Abrasion Test of Fabrics. . Textile Testing Quiz-4: 34: Advanced Fibre Information System (AFIS) Textile Testing Quiz-5: Textile Testing Quiz-5: 13: Module Name DownloadThe method specifies a procedure to determine the tear strength of textile fabrics using the trouser method. A rectangular specimen is cut in the center of the shorter dimension to form a trouser shape. . Each leg of the trouser is inserted into the grip faces and pulled to tear the fabric. For this test, it is important to have an increased . Fabric tear resistance is crucial for safety, product durability, and customer satisfaction. . ASTM D1424: Standard test method for tearing strength of fabrics by the trapezoid procedure. ISO .The standards used worldwide for fabric tear strength are: ISO 4674-1998 Part-1: Determination of tear resistance. ISO 13937-3-2000 Textiles- Tear properties of fabric-part 3: Determination of tear strength of wing-shaped test specimens. ISO 13937-1-2000 Textiles: Determination of tear force using the ballistic pendulum method

water vapor permeability testing equipment vendor

water+vapor+permeability+tester vendor

Mega Deportes TV sitio para ver canales de futbol y deportes online en vivo y en directo gratis por internet. Ver Canales de futbol y deportes gratis online en vivo y en directo .

tear strength fabric testing|tearing strength tester